Features:

1.Machine with automatic function, such as feeding, counting, filling, sealing, cutting, printing the date information and cutting the easy tearing notch.

2.Machine with counting systems, vibration bowls & counting bowls could customized.

3.Each machine are customized, efficient, flexible, reliable, low maintenance, productive, safe, pneumatic system, reliable working and convenient maintenance.

4.With PLC control, the length of the bag can be set and cut on one step, saving time and film.

5.High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

6.Temperature independent PID control, more suitable for packing different materials.

7.Positioned stop function, without sticking knife or wasting film.

8.All control is realized through software, easy for function adjusting and technical upgrade.

9.Touch screen easy and quick setting and operation.

10.It can count and pack the same item or mixed items into the package.

Following Devices are Optional:

1.Automatic Feeding Machine:

A)Automatic Bottle Feeder

B)Automatic Paper Book Feeder

C)Automatic Paper Folder

D)Automatic Counting Feeder

E)Automatic Blister Feeder

2.Labeling Machine:

A)Labeling Machine ONLY

B)Labeling Machine with Printing Device

3.Date Printer:

A)Laser Printer

B)Inkjet Printer

4.Automatic Sorting Line

A)Automatic Rotary Table for Bottles

B)Bar Bag Sorting Line

5.Weight Checker

6.Metal Detector

7.Horizontal Wrapping Machine

8.Glue Device

|

Model

|

VGO-HC1990

|

|

Packing Speed

|

60-120 boxes/min

|

|

Box Size

|

Max. 190×90×40mm

Min 80×20×15mm

(Customized is available)

|

|

Box Quality Requirement

|

Gray cardboard: 300-350g/m³

|

|

|

White cardboard: 250-350g/m³

|

|

|

Corrugated paper: To be confirmed

|

|

Power

|

2.0 KW

|

|

Voltage

|

380V 50/60 HZ

|

|

Air

|

0.5-0.8 Mpa, 20m³/h

|

|

Dimension

|

3316(L)×1230(W)×1884(H) mm

|

|

Machine Weight

|

1500 kgs

|

1. Packing speed up to 120 boxes per minute, which is 2-3 times of the speed of others model.

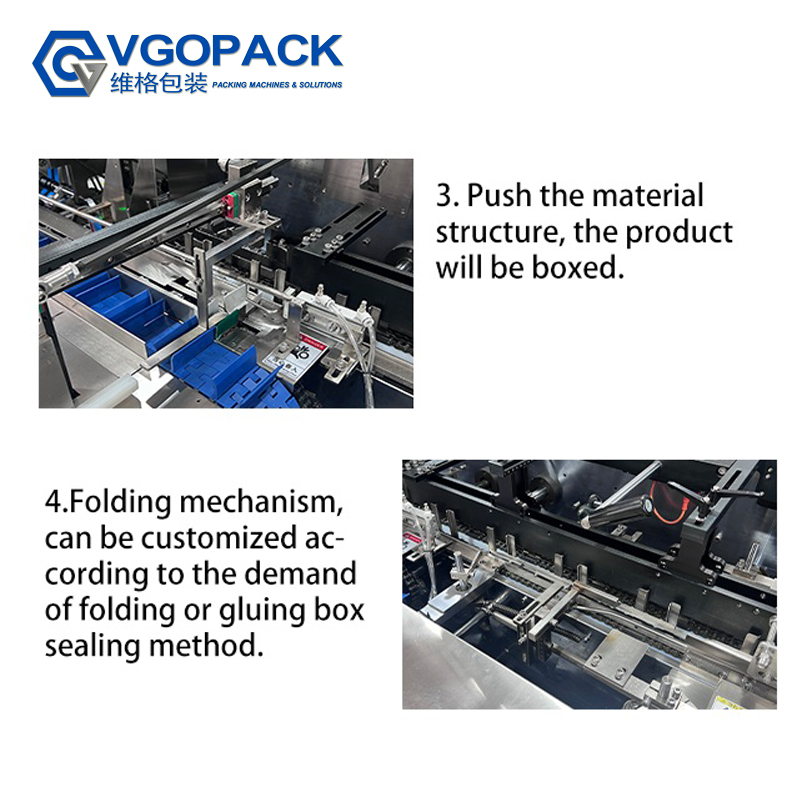

2. It can realize automatic box opening, product filling, packing and sealing. It can be customized according to project requirements.

3. The machine is controlled by PLC. Photoelectric monitoring of various parts of the operation is abnormal, and the machine can automatically stop to display the cause so as to eliminate the fault in time.

4. The main drive motor and clutch brake are installed inside the frame, and the torque overload protection device of each part of the transmission system is installed on the machine board, which can realize the disconnection of the main drive motor and transmission parts under overload conditions to ensure the safety of the whole machine.

5. The machine is equipped with an intelligent detection device. When there is a lack of materials, the machine does not discharge the material, which is convenient for matching with other equipment.

6. The machine can be used alone or in conjunction with other equipment to realize the operation of the entire production line.

7. The packaging specifications can be changed according to the different requirements of project, and the adjustment and testing are simple. It is not only suitable for the production of large quantities of single varieties, but also can meet the production of small batches of multiple varieties of products.

8. The equipment with product counting and running speed display functions.

1.One year quality warrant if no human damage

2.OEM service ,design service and buyer label is offered

3.24 hours/365 days online technical support service

4.Warmly welcome to visit our factory

Phone:+86 19832873226

Email:sales@vgopack.com

WhatsApp/WeChat/Skype:+ 86 19832873226

Contact Person:Amy Liu

Address:Room 303, Building 2, Wanyang Chuangzhi Park, No. 82 of Xiaotang Industrial Avenue, Shishan Town, Nanhai District, Foshan City, Guangdong, China