Key Features:

1.Comprehensive Functionality: The machine independently performs a series of tasks, including bag pickup, date printing, bag mouth opening, filling, compaction, heat sealing, shaping, and output of finished products.

2.Versatile Material Handling: Suitable for multiple materials, offering a wide adaptation range for different packaging bags.

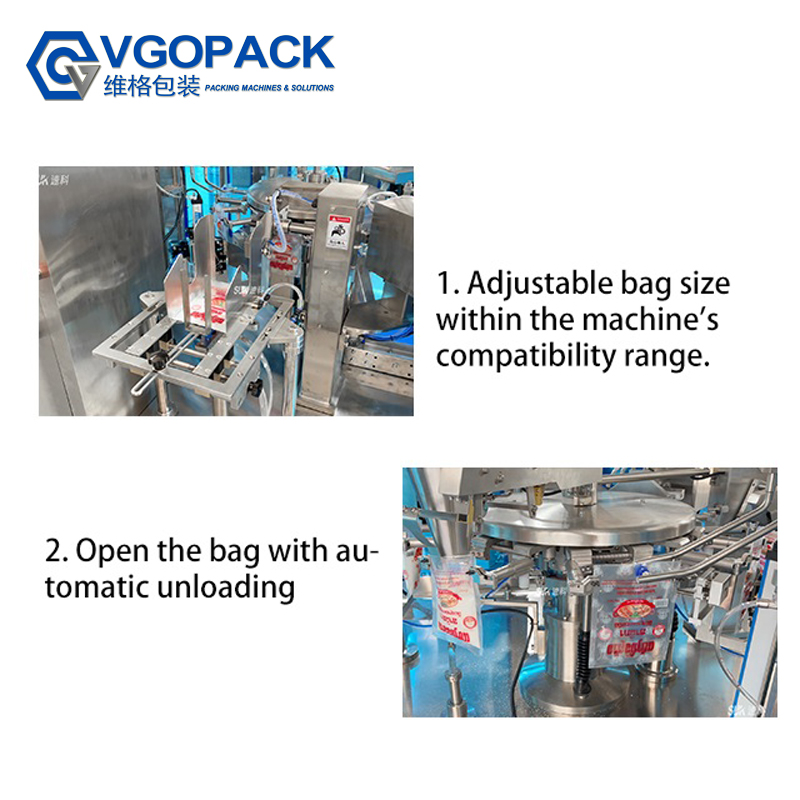

3.User-Friendly Operation: Intuitive, simple, and easy to operate, with adjustable speed and quick changes to packaging bag specifications.

4.Automatic Detection and Safety Monitoring: Features automatic detection and safety monitoring functions, reducing packaging material loss and ensuring perfect sealing and appearance.

5.Multiple Filling Devices: Can be equipped with various filling devices such as intelligent combination scales, auger weighing devices, liquid or paste filling devices, measuring cup filling devices, and others for special products. It can also be integrated with external matching equipment to replace conventional manual packaging, achieving automated packaging and production.

6.Stainless Steel Construction: The machine is constructed from stainless steel, ensuring hygiene and safety.

7.Servo Motor for Main Power: Adopts a servo motor for stable operation and high speed. In case of metering scale faults or material shortages, the machine stops and waits for material, automatically resuming when material is available, thereby improving production efficiency and reducing packaging bag wastage.

8.Compatible Bag Types: Suitable for various bag types including four-side-sealed bags, three-side-sealed bags, self-standing bags, handbags, zipper bags, plastic bags with covers, and paper-plastic bags.

9.Material Compatibility: Capable of handling a variety of materials such as liquids, sauces, granules, powders, and irregularly shaped items.

10.Packaging Bag Materials: Compatible with preformed bags and paper-plastic bags made from multiple composite films.

Following Devices are Optional:

1.Output Belt Conveyor

2.Date Printer:

A) Hot Stamp Printer

B) Thermal Printer

3.Weight Checker

4.Metal Detector

|

Model

|

VGO-8P200-MW

|

|

Weigher

|

10 Heads weigher, 14 heads weigher

|

|

Mechanical Working Station

|

8 station

|

|

Bag Type

|

Stand-up bags, handbags, four-side sealing bags, zipper bags, three-side sealing bags, spout bags, paper bags, etc.

|

|

Bag Width

|

50-200 mm

|

|

Bag Length

|

100-400 mm

|

|

Packing Speed

|

20-60 bags per minute (It depends)

|

|

Filling Range

|

10g-2500 grams

|

|

Size Adjustment

|

The rocker controls all workstations to be adjusted together

|

|

Noise Decibels

|

≤70 decibel

|

|

Machine Weight

|

1400 kgs

|

|

Voltage and Power

|

380V 50HZ 9.8KW

|

|

Air consumption

|

≥0.6 m³/minute

|

|

Dimension

|

2480×1600×1483mm

|

|

Machine Frame

|

Exposed and material contact parts are all 304 stainless steel

|

|

|

Transmission and support frame all steel

|

Granules: monosodium glutamate, granular drugs, capsules, seeds, chemicals, sugar, chicken essence, melon seeds, nuts, pesticides, fertilizers.

Powdered: milk powder, glucose, monosodium glutamate, seasoning, laundry detergent, chemical raw materials, sugar, pesticides, fertilizers and so on.

Liquid or Paste: detergent, soy sauce, rice vinegar, fruit iuice, curry paste, ketchup, peanut buter, jam, chii sauce, bean paste and other seasonings.

Mixture ingredients: beef cubes with stock, minced meat with ketchup.

Lumpy materials: dried fruits, prepared vegetables, candies, cereals, chocolates, cookies, peanuts and nuts, pickled cabbage, sauerkraut, etc.

1.One year quality warrant if no human damage

2.OEM service ,design service and buyer label is offered

3.24 hours/365 days online technical support service

4.Warmly welcome to visit our factory

Phone:+86 19832873226

Email:sales@vgopack.com

WhatsApp/WeChat/Skype:+ 86 19832873226

Contact Person:Amy Liu

Address:Room 303, Building 2, Wanyang Chuangzhi Park, No. 82 of Xiaotang Industrial Avenue, Shishan Town, Nanhai District, Foshan City, Guangdong, China